יום פתוח בטכניון

בואו להכיר מקרוב את הטכניון ביום הפתוח ב-5/3 בקמפוס הטכניון בחיפה

פרופ' דבי לינדל מהפקולטה לביולוגיה זכתה בפרס אוולין האצ'ינסון באוקיינוגרפיה והתקבלה לאקדמיה האמריקאית למיקרוביולוגיה

הרצאתו של ד"ר יותם בר-און מהפקולטה לרפואה ע"ש רות וברוך רפפורט : מדוע הנגיפים תמיד מנצחים?

מדד CSRankings מדרג את הטכניון במקום הראשון באירופה בתחום ה-AI על פי נתוני 2025-2005

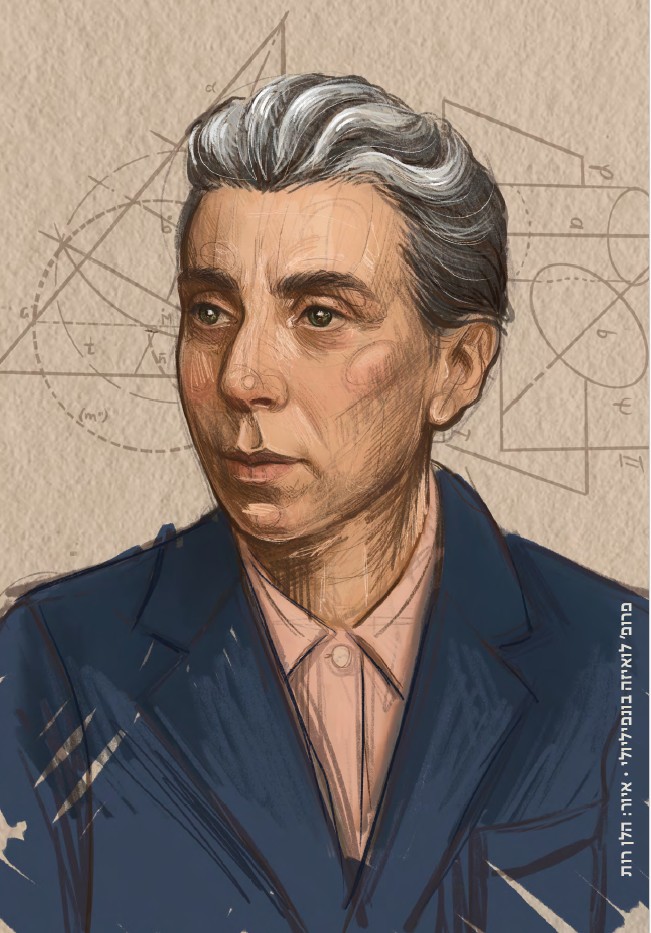

הכנס הישראלי השני לפילוסופיה של בינה מלאכותית

04.03.2026 רביעי, בשעה 09:30

הוספה ליומן

יום פתוח בטכניון 5.3

05.03.2026 חמישי, בשעה 09:30

הוספה ליומן

תערוכת "מראות מקום"

30.11.2025 ראשון, בשעה 09:00

הוספה ליומן

תערוכת הצילום "טבע בקמפוס"

16.07.2025 רביעי, בשעה 09:00

הוספה ליומן

100000

בוגרים

18

פקולטות

15000

סטודנטים

60

מרכזי מחקר

ברחבי הקמפוס